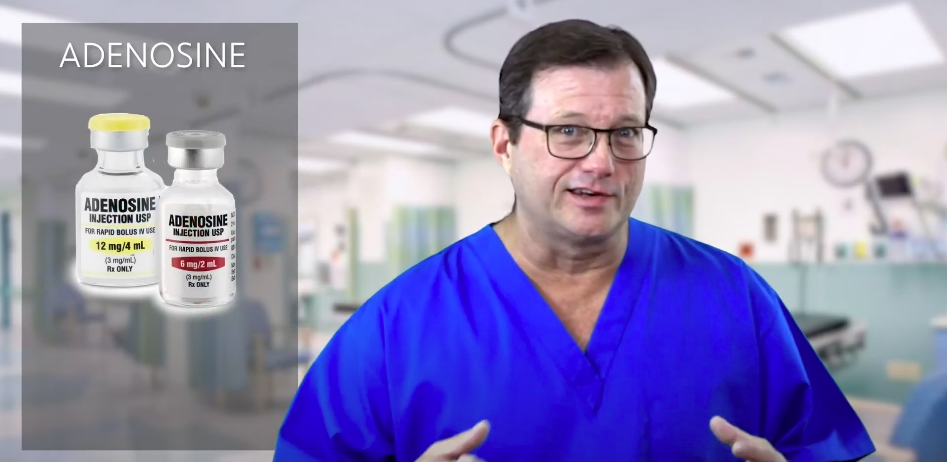

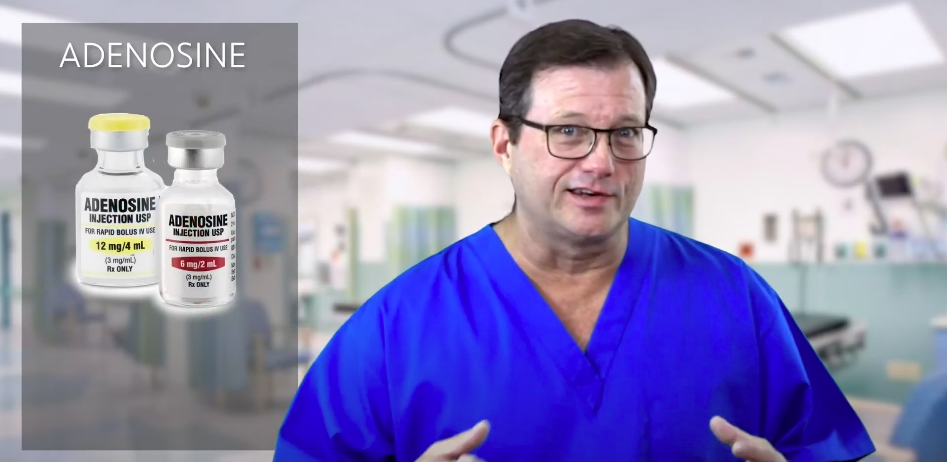

A resilient supply chain for high-purity actives like Adenosine depends on strategic partnerships with certified manufacturers, reliable suppliers, and efficient distributors. The integrity of the entire chain, from synthesis to final delivery, must be rigorously vetted to ensure the material meets pharmaceutical grade or cosmetic grade standards.

The adenosine manufacturer (like Huatai Bio) is the origin of the quality. Their adherence to international quality systems, such as ISO 9001 Quality Management System and ISO 22000 Food Safety Management System, is the baseline for B2B trust. The manufacturer is responsible for achieving and certifying the 98% purity of the raw material.

The adenosine manufacturer (like Huatai Bio) is the origin of the quality. Their adherence to international quality systems, such as ISO 9001 Quality Management System and ISO 22000 Food Safety Management System, is the baseline for B2B trust. The manufacturer is responsible for achieving and certifying the 98% purity of the raw material.

Procurement often involves dealing with the adenosine supplier or distributor, who must guarantee that the quality achieved by the manufacturer is maintained throughout logistics. The distributor facilitates the complex global transactions and ensures timely delivery of the bulk powder.

For B2B buyers vetting the supply network:

Manufacturer Quality Vetting: The manufacturer's compliance must be verified by the COA (Certificate of Analysis), confirming the 98% purity and the absence of contaminants. The MSDS (Material Safety Data Sheet) from the manufacturer is mandatory for safety protocol setup.

Supplier and Distributor Reliability: The supplier or distributor must provide a complete Technical Dossier, including the TDS (Technical Data Sheet) for technical formulation support. Their ability to handle buy adenosine wholesale orders efficiently is crucial.

Grade Management: The manufacturer and supplier must clearly define and certify the material as either pharmaceutical grade adenosine or cosmetic grade adenosine, meeting the distinct regulatory needs of the final product.

In conclusion, strategic sourcing of adenosine requires a certified manufacturer and a reliable supplier or distributor who can consistently deliver the required pharmaceutical grade or cosmetic grade material.

The adenosine manufacturer (like Huatai Bio) is the origin of the quality. Their adherence to international quality systems, such as ISO 9001 Quality Management System and ISO 22000 Food Safety Management System, is the baseline for B2B trust. The manufacturer is responsible for achieving and certifying the 98% purity of the raw material.

The adenosine manufacturer (like Huatai Bio) is the origin of the quality. Their adherence to international quality systems, such as ISO 9001 Quality Management System and ISO 22000 Food Safety Management System, is the baseline for B2B trust. The manufacturer is responsible for achieving and certifying the 98% purity of the raw material.Procurement often involves dealing with the adenosine supplier or distributor, who must guarantee that the quality achieved by the manufacturer is maintained throughout logistics. The distributor facilitates the complex global transactions and ensures timely delivery of the bulk powder.

For B2B buyers vetting the supply network:

Manufacturer Quality Vetting: The manufacturer's compliance must be verified by the COA (Certificate of Analysis), confirming the 98% purity and the absence of contaminants. The MSDS (Material Safety Data Sheet) from the manufacturer is mandatory for safety protocol setup.

Supplier and Distributor Reliability: The supplier or distributor must provide a complete Technical Dossier, including the TDS (Technical Data Sheet) for technical formulation support. Their ability to handle buy adenosine wholesale orders efficiently is crucial.

Grade Management: The manufacturer and supplier must clearly define and certify the material as either pharmaceutical grade adenosine or cosmetic grade adenosine, meeting the distinct regulatory needs of the final product.

In conclusion, strategic sourcing of adenosine requires a certified manufacturer and a reliable supplier or distributor who can consistently deliver the required pharmaceutical grade or cosmetic grade material.